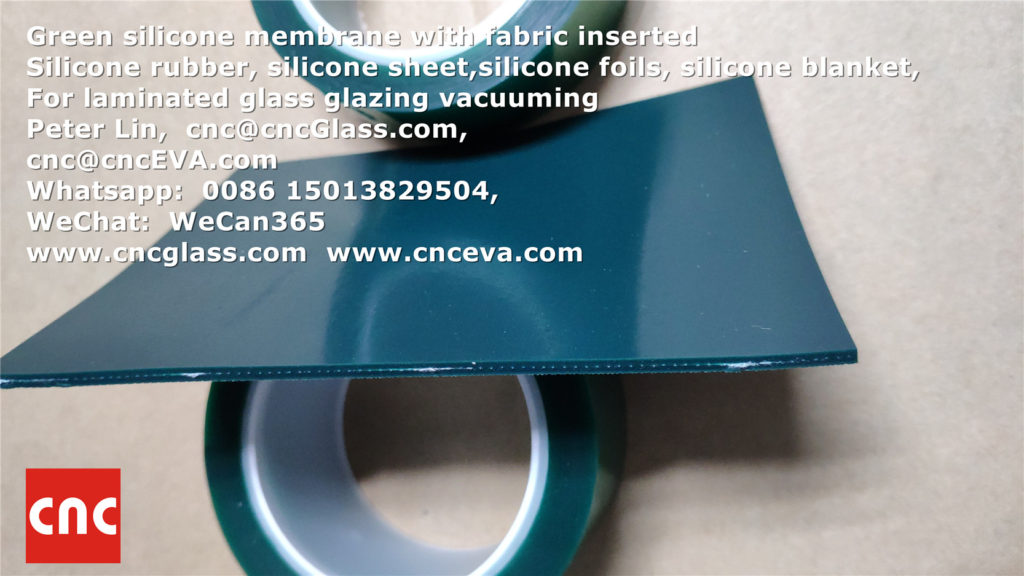

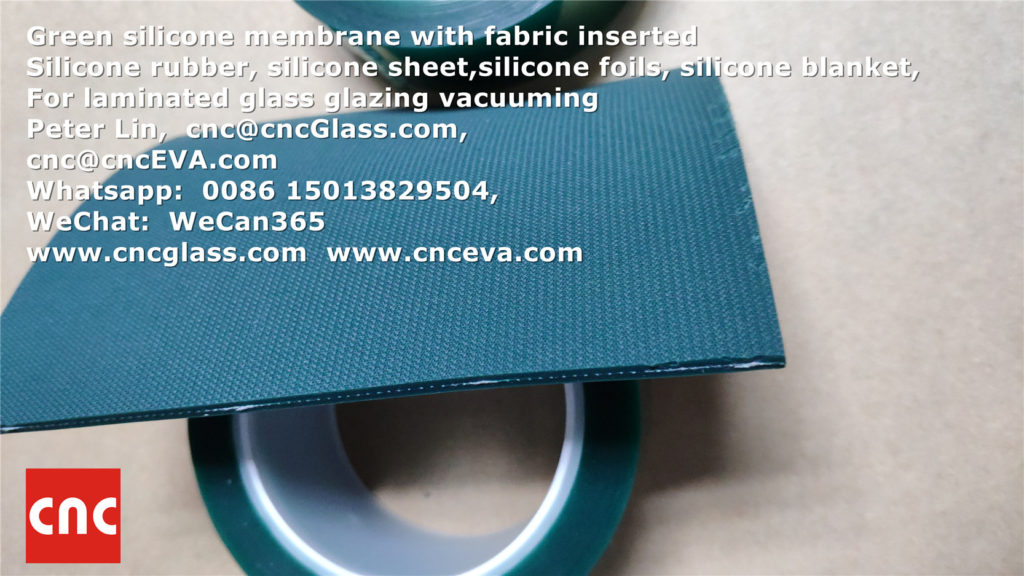

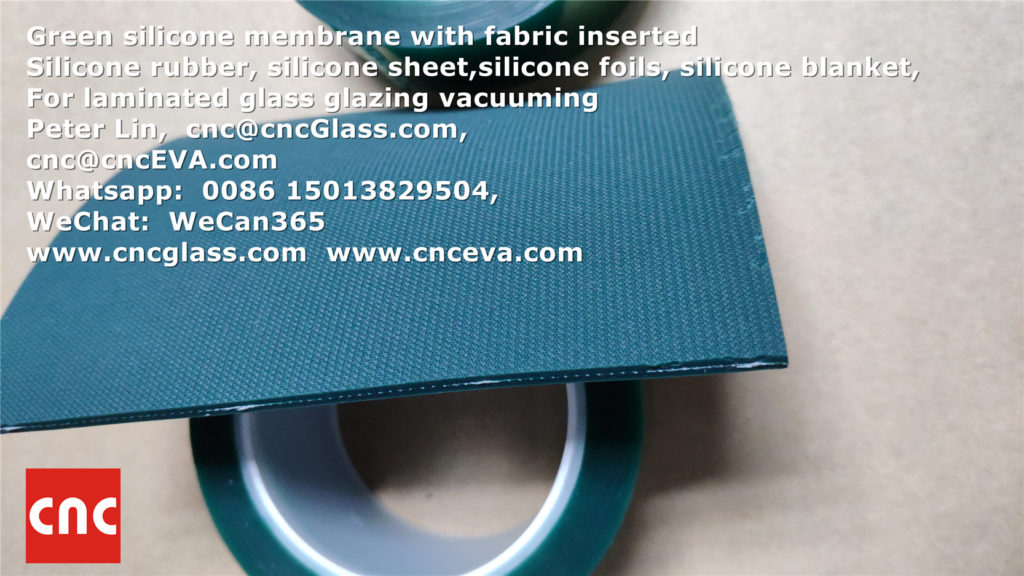

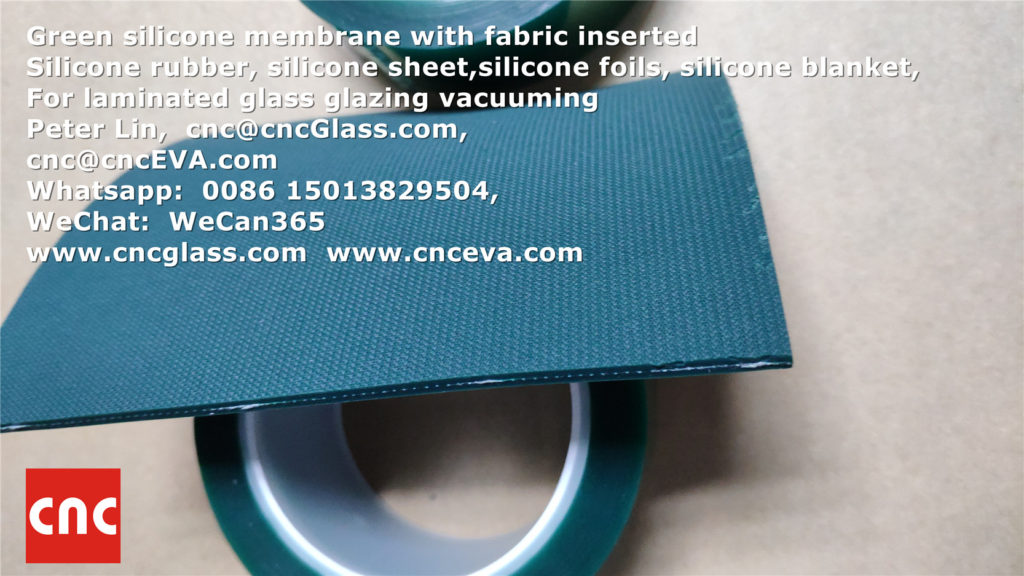

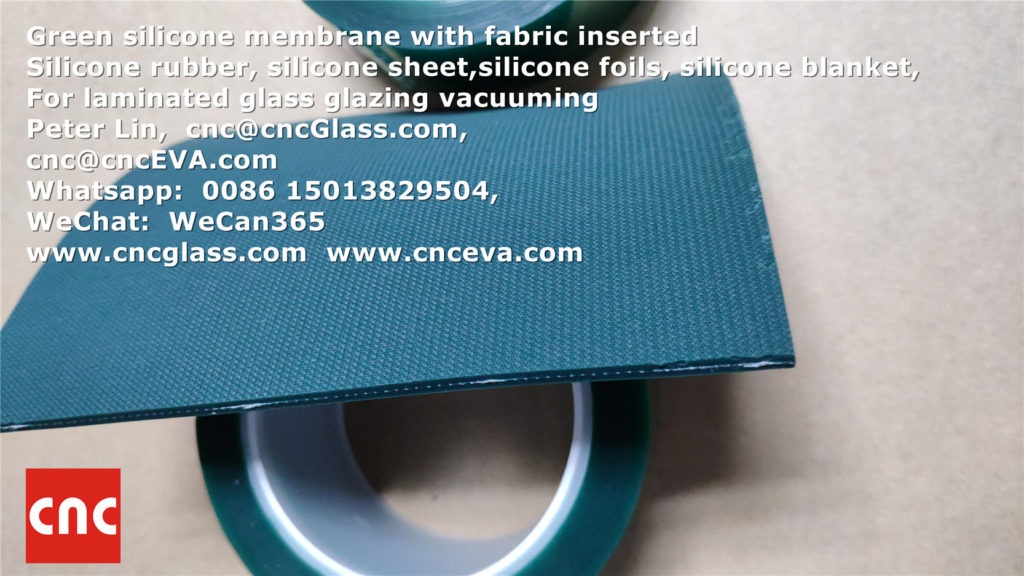

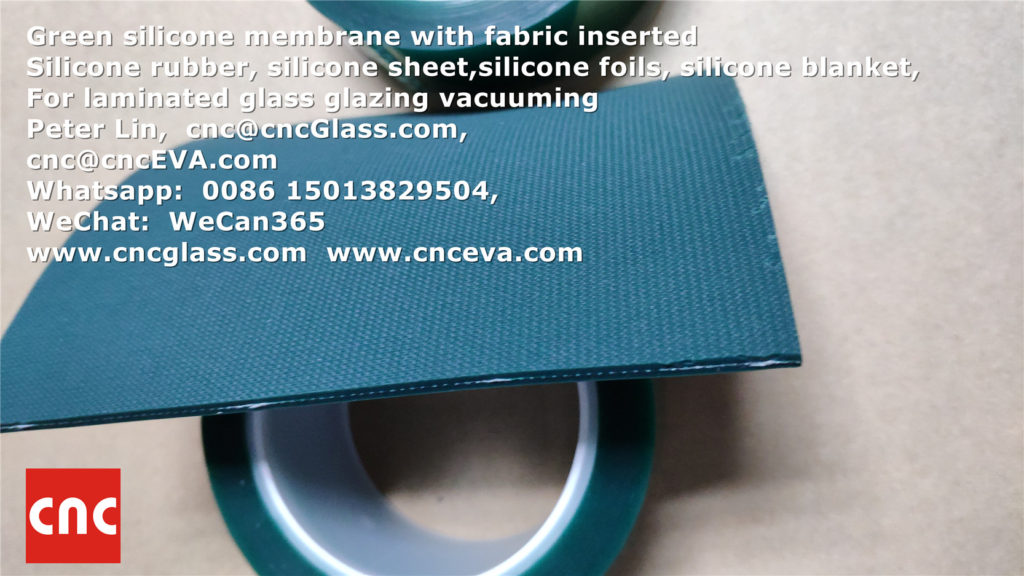

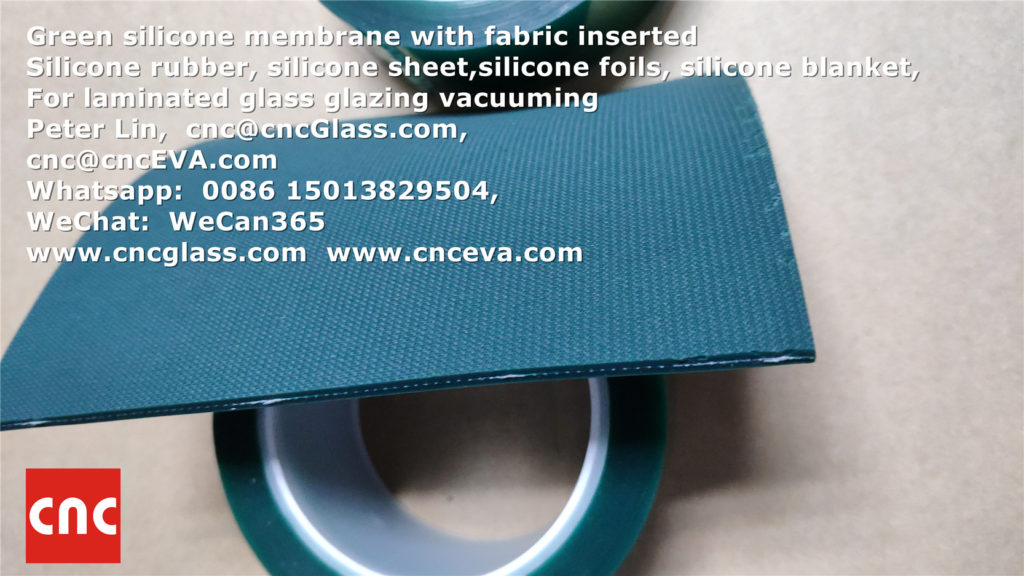

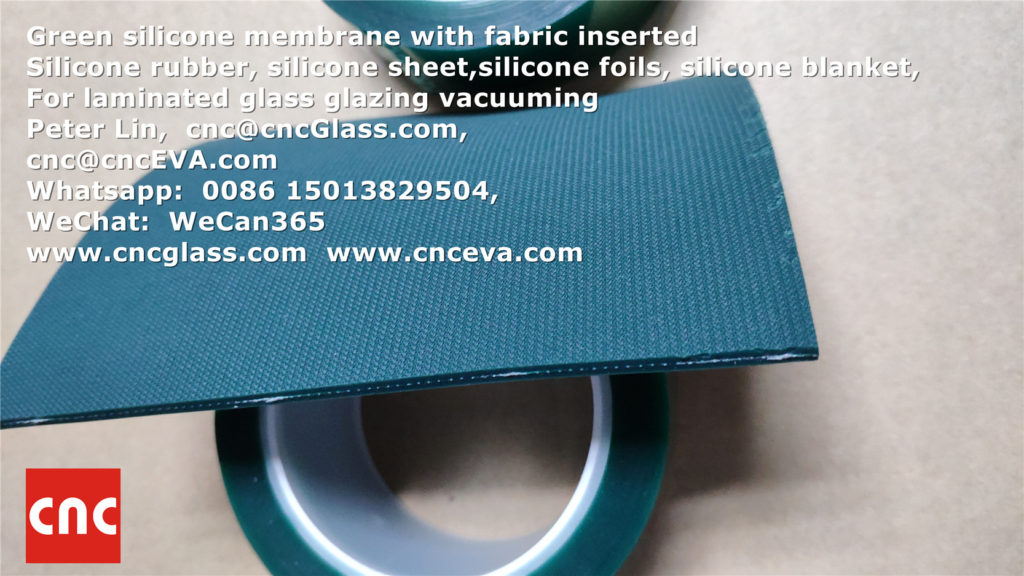

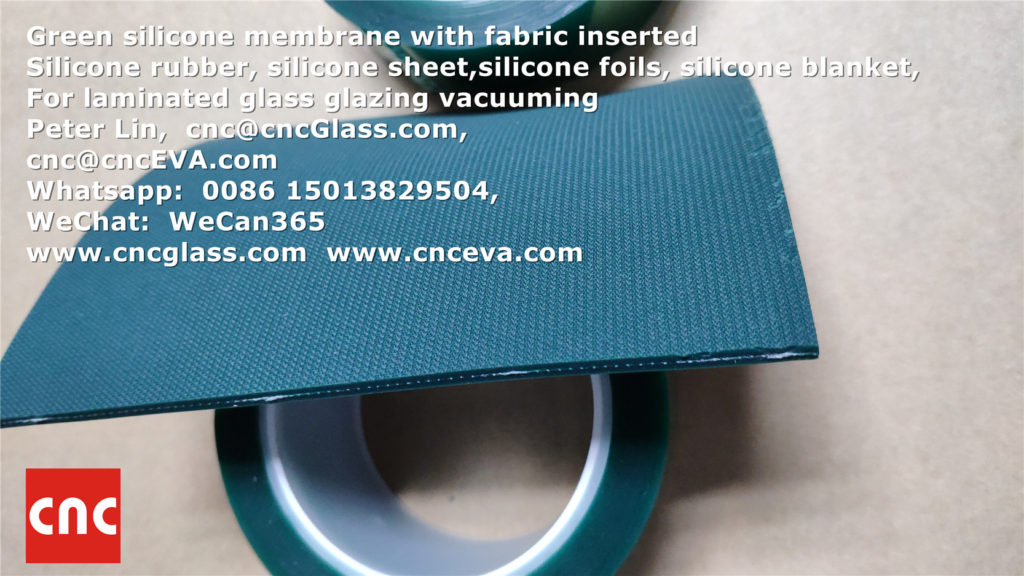

high tear resistance silicone thin sheet for lamination vacuum press machine

high tear resistance silicone thin sheet for lamination vacuum press machine

high tear resistance silicone thin sheet for lamination vacuum press machine

high tear resistance silicone thin sheet for lamination vacuum press machine

silicone rubber sheets silicone bag for glass lamination vacuuming

Camila Cabejo is not spending this summer alone, but in the company of her new lover. Paparazzi filmed the singer on a walk together with a mysterious handsome man. And later, journalists found out that the star’s chosen one was Austin Kevitch. We tell you what you need to know about this guy. Austin and Camila were introduced by their mutual friends. If rumors are to be believed, Kevich wanted to be friends with Kabayo, so he asked his mates to arrange for them to meet. They ended up finding common Camila Cabello weight gain break up ground and began spending a lot of time together. According to reporters, Austin even attended the singer’s birthday party. Kevich grew up in Pennsylvania in a large family. As a teenager, he was fond of soccer and even took part in the Global Bowl France as a member of the U.S. national team. After high school he went to Bucknell University, where he studied business, computer engineering and psychology from 2010 to 2014. Austin is now known as the co-founder and CEO of the dating app Lox Club, which appeared in the pandemic and was loved by many Americans. It’s worth noting that it’s not the only platform Kevich has created. He also invented Brighten, a platform that allows people to write nice comments to each other.

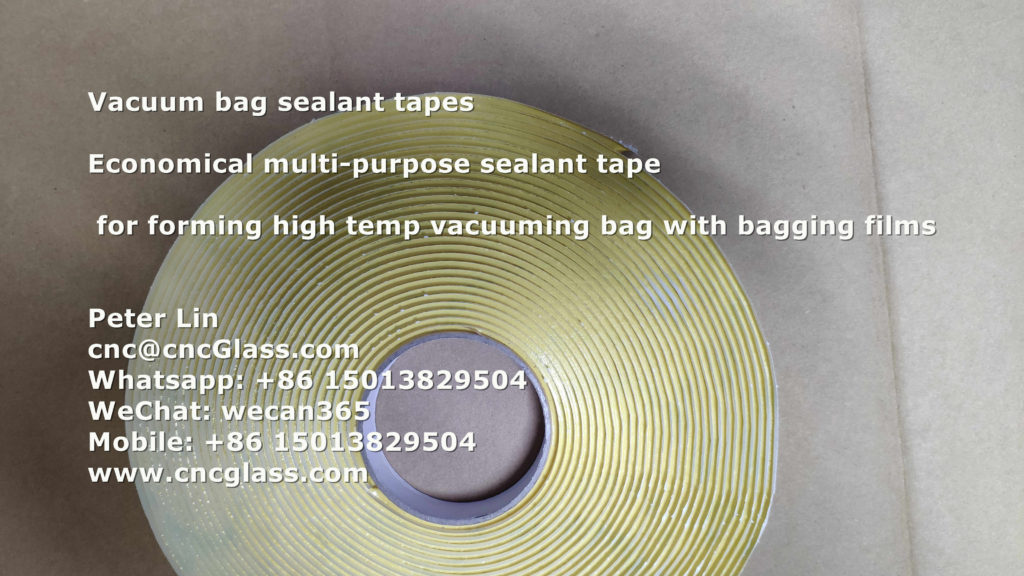

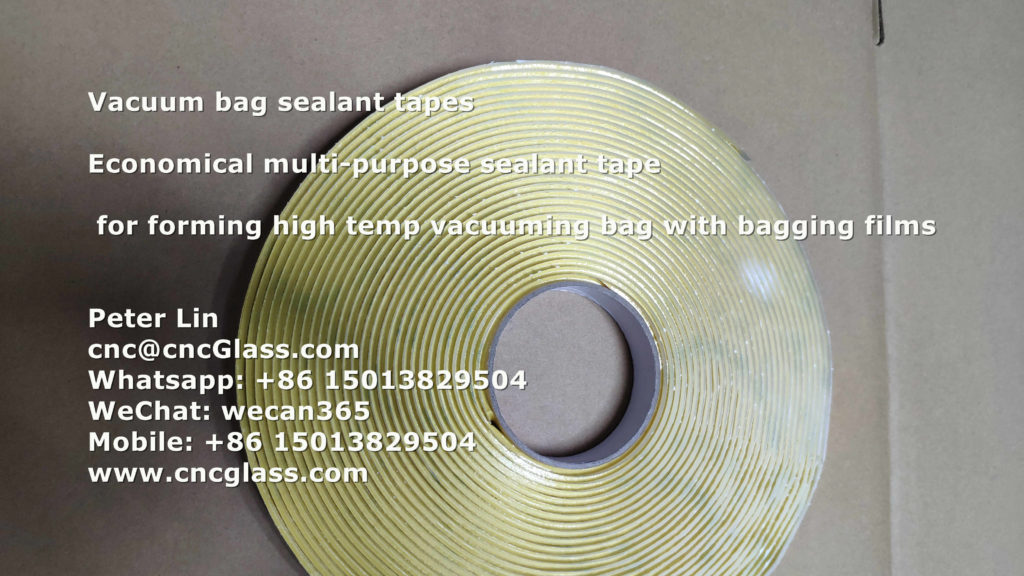

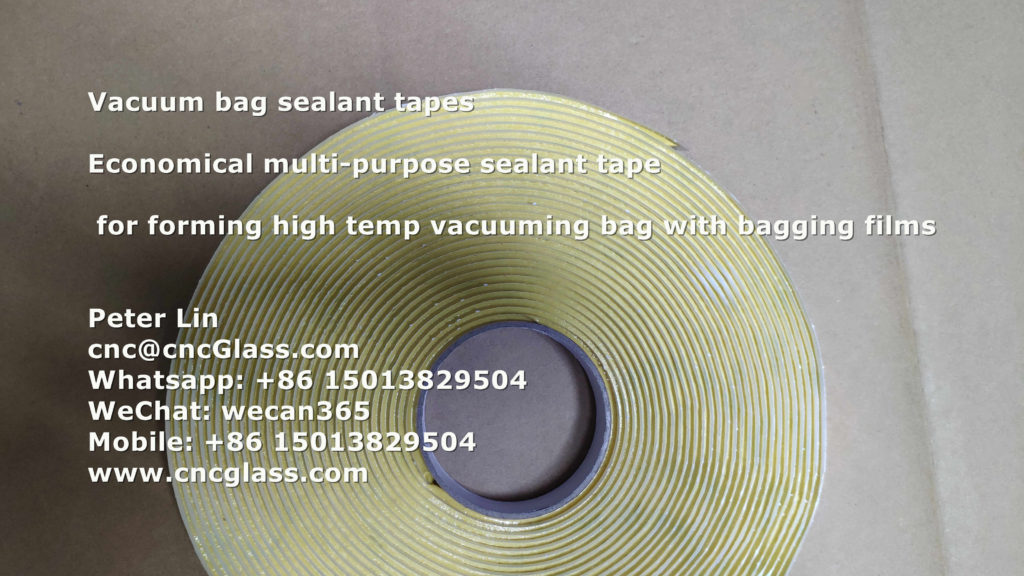

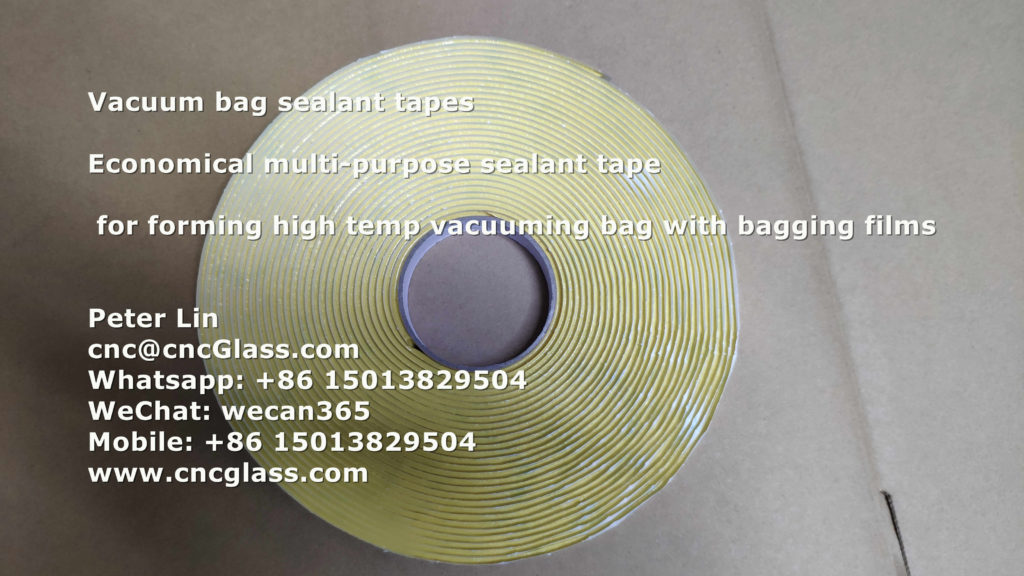

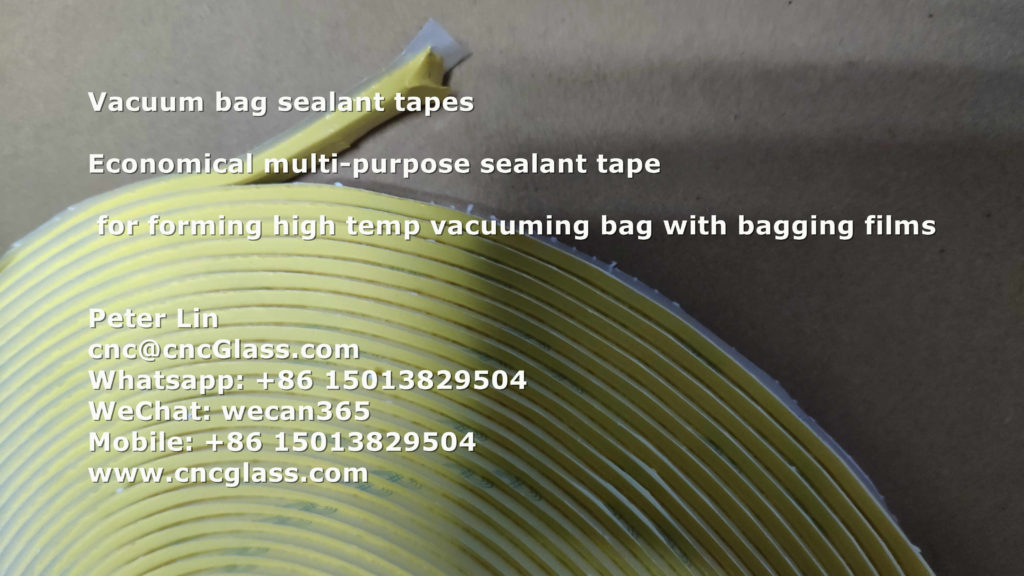

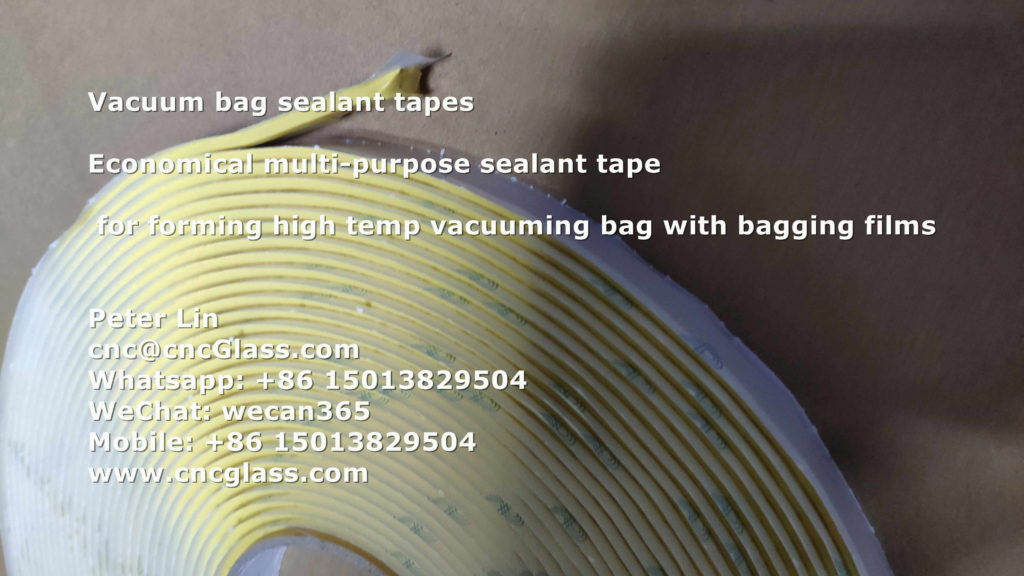

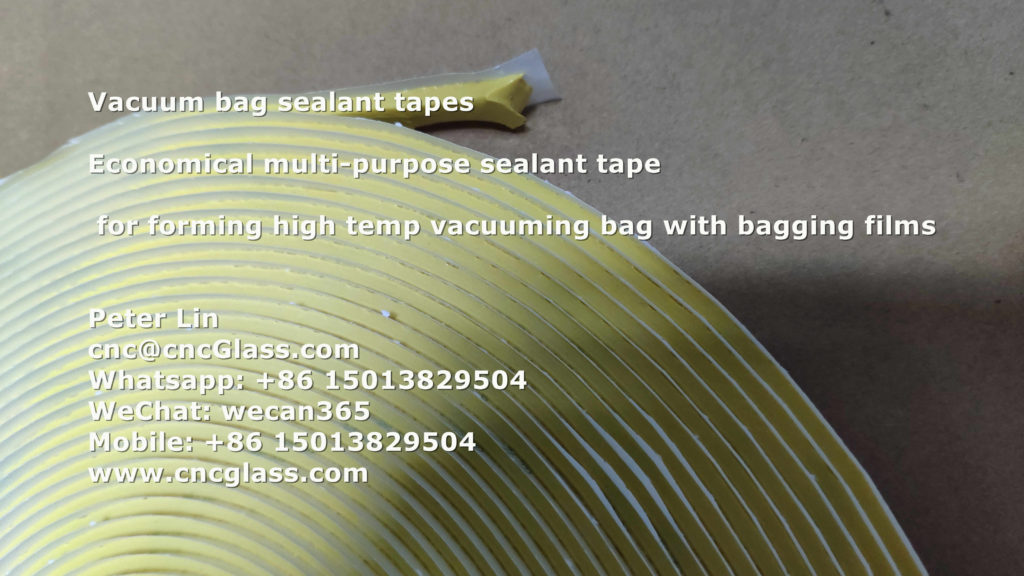

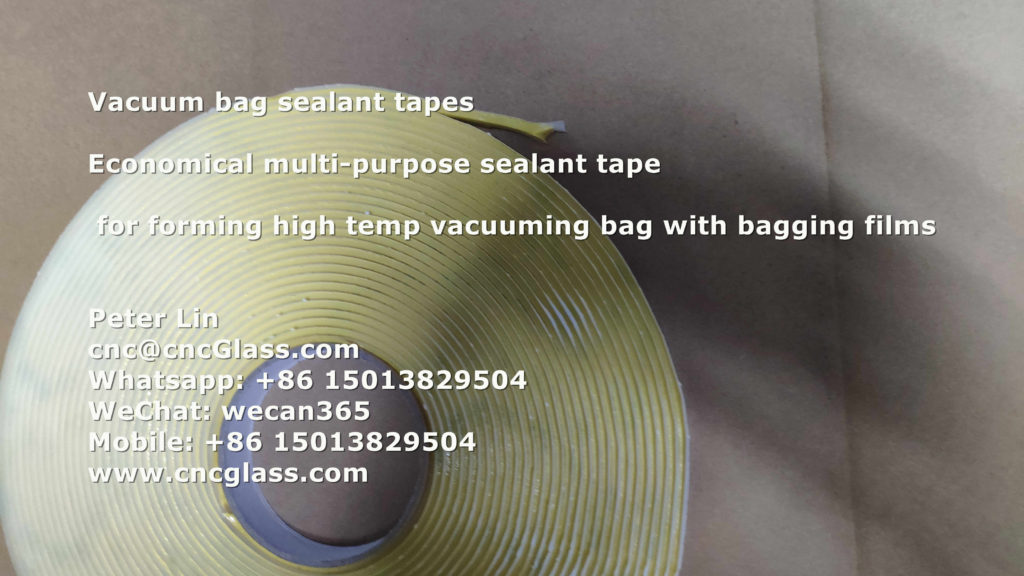

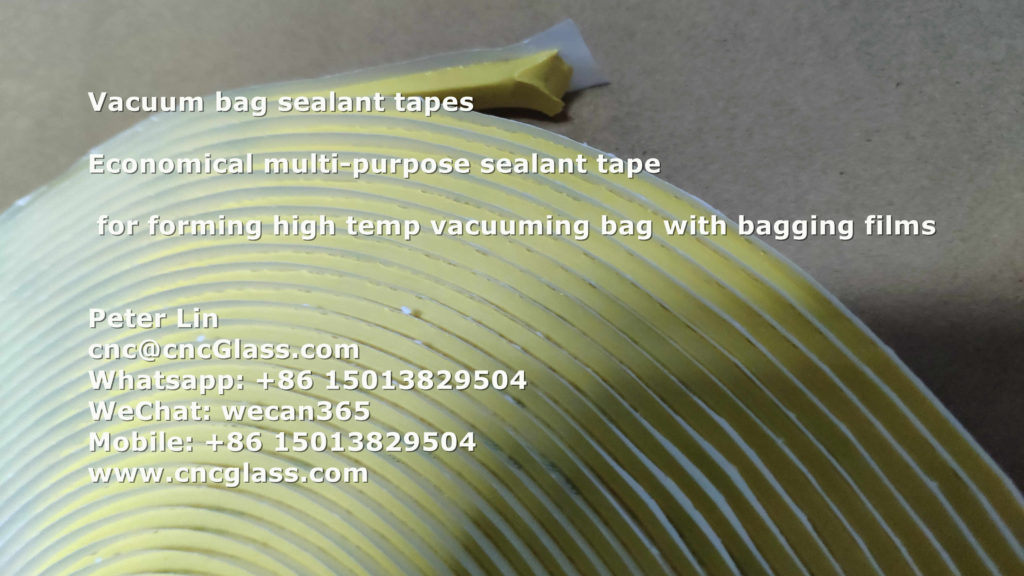

Vacuum bag sealant tapes

Economical multi-purpose sealant tape

for forming high temp vacuuming bag with bagging films

Peter Lin

[email protected]

Whatsapp: +86 15013829504

WeChat: wecan365

Mobile: +86 15013829504

www.cncglass.com

Vacuum bag sealant tapes Economical multi-purpose sealant tape Yellow sealant tape

*Yellow sealant tape is an economical multi-purpose sealant tape with high temp resistance. It’s uitable for cure applications up to 400F(204C).

*Economical vacuum tape reduces the cost of vacuum bagging.

*Multi-purpose tape can be used on metal and composite tooling.

*Easy clean up reduces cost of tool cleaning.

Product Info:

Yellow

Synthetic rubber

Maximum use temperature: 400F(204%C)

Shelf life:12 months from date of manufacture

Tape must be stored flat in original packaging at 72F(22″C); Do not refrigerate

3 mmx 12 mm*15meters per roll

Application notes:

*For clean removal,it is recommended to strip the tape from the mold surface once it has cooled down to room temperature.

*The maximum use temperature depends upon the duration at maximum temperature, and we recommend clients testing prior to use.